Solar cover for the pool - yes or no?

How does a solar pool cover work?

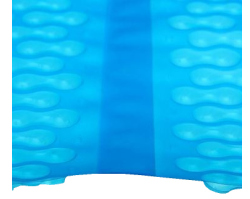

Solar covers are designed to cover the surface of both outdoor and indoor pools. In the case of an outdoor pool, the cover prevents water evaporation and contributes to its partial heating through the solar effect on sunny days. Heating the water in the pool is a common topic of discussion on various forums. Opinions vary. Some say yes, others say no.

Test of the Effects of the Solar Cover

For this reason, we conducted an actual test of the solar cover on a real outdoor swimming pool measuring 6 x 3.5 meters with a water volume of 30 cubic meters. The test was carried out in June 2017 for a duration of 10 days.

- Solar Cover Type: 400 micron blue

- Daily Temperatures during Measurement: 15 - 27°C

- Night Temperatures during Measurement: 13 - 16°C

- All measurements were taken 1 meter below the water surface.

Results of Measured Temperatures:

We found that a solar cover placed on the surface of the pool during the day when the sun is shining can effectively heat the water by 3 - 6°C per day. Without a solar cover, the water heats up by 1 - 2°C.

During the morning temperature measurements with the cover laid on the surface, we recorded a nighttime temperature drop of 1 - 2°C. Without a solar cover, it is 3 - 6°C.

Significance of a Cover for Indoor Pools

For indoor pools, a cover primarily prevents the evaporation of heated water and, consequently, the loss of heat from the pool. Additionally, it prevents water condensation in the room and the formation of mold on the building structure. Anyone who has an indoor pool is surely familiar with the inconveniences related to humidity and water vapor condensation in the pool area. Of course, an indoor pool should have adequate ventilation or dehumidification. However, the continuous operation of these systems is financially demanding, not to mention the potential noise generated by fans during dehumidification. A cover placed on the water surface drastically reduces the need to dehumidify the space. This is particularly true at night when nobody is using the pool, making energy consumption entirely unnecessary.

Material for Manufacturing a Solar Cover

Welding cylinders

Ultrasonic welding

How is a solar pool cover made?

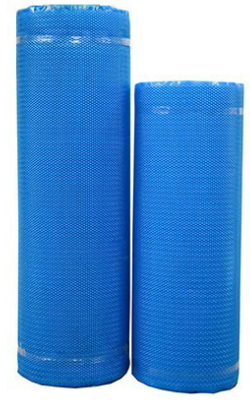

Solar pool covers are manufactured in various material thicknesses and colors. The material used for making the covers is UV-stabilized polyethylene. Two layers of LDPE film (Low-Density Polyethylene) are thermally bonded on special rolls. One side of the roll is equipped with protrusions, which then form bubbles on the cover. The bottom layer always remains smooth. The resulting thickness of the cover depends on the thickness of the base film used in production. Different widths of the base material for manufacturing a solar pool cover can be produced based on the width of the roll.

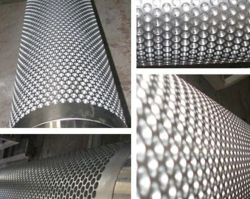

Machines for manufacturing solar pool covers

The widths of rolls for basic production vary. The narrowest widths are 1 meter, and the widest rolls can reach up to 2.5 meters.

There are inquiries about whether there exists a cover made from a single piece – meaning without seams. Given the nature of the width of the base material, it's clear that a cover wider than 2.5 meters cannot be produced without seams.

Prepared strips of film are then welded together, resulting in the final width of the solar pool cover. There are two methods for welding solar covers.

1.Ultrasonic Welding

This method is primarily used for higher-quality solar pool covers with a thickness of 360 microns and above. For this type of cover, a strip without bubbles is already prepared on both sides of the base strip during production. These two smooth strips are overlapped and welded together using an ultrasonic welding machine. Therefore, when you purchase a solar pool cover welded by ultrasonic means, it has strips without bubbles in the center and along the edges. These can be trimmed with scissors.

It is generally believed that ultrasonic welding creates a higher-quality and more flexible joint with a longer lifespan. There is not as much material degradation as with hot air welding. Solar pool covers welded by ultrasonic means are available only in standard widths and need to be trimmed to the exact dimensions of the pool.

Ultrasonic Welding of the Cover

2.Hot Air Welding

This method is used for thinner covers up to a thickness of 360 microns, exceptionally 400 microns. The production process of the base strip is almost identical to covers intended for ultrasonic welding, except there is no smooth strip on the sides. Covers are welded by overlapping two strips directly onto the bubbles. This results in a harder weld, which slightly reduces the flexibility of the cover. During welding, the bubbles on both welded layers deform. This welding method requires the correct welding temperature and the skill of the welder.

Covers welded with hot air can also be purchased cut precisely to size, or to fit the shape of the pool (round covers, oval covers). Due to the production process, a dimensional deviation of up to 5% is specified, which for larger covers can result in a quite significant difference. From practice, we know that covers are usually larger than the desired size. In such a case, the cover can be trimmed directly to size on the pool, just like with ultrasonic welding.

Benefits of a Solar Pool Cover:

- Prevents water evaporation

- Reduces the consumption of pool chemicals

- Heats the water in the pool

- Maintains water temperature

- Relatively low cost compared to other pool cover options.

Disadvantages of a Solar Pool Cover:

- More complicated handling, especially for larger pools, without a reel.

- Takes up more storage space.

- The material is not frost-resistant.